Text of the exercise:

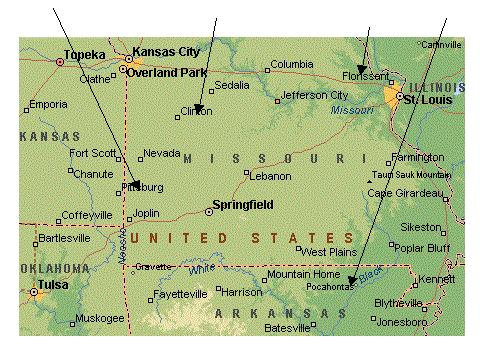

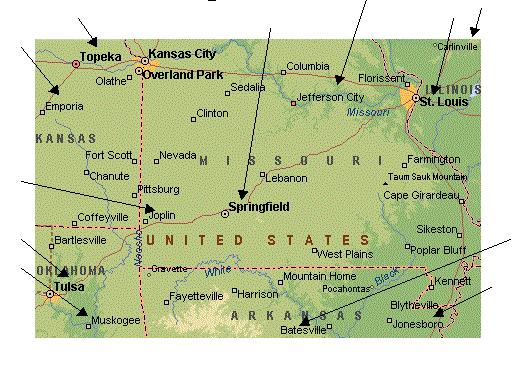

There is a distributed car manufacturing organization, with 4 production sites located in:

The models of cars produced (subdivide between luxury car and compact car) are 6:

For the next year are expected 2 new models:

The carís production is distributed as following:

|

Car Model |

Pittsburgh |

Clinton |

Pocahontas |

Florissant |

Total for car |

|

Car Frenchie |

200.000 |

100.000 |

- |

- |

300.000 |

|

Car Ago |

100.000 |

100.000 |

- |

- |

200.000 |

|

Car Panettone |

- |

- |

- |

200.000 |

200.000 |

|

Car Edsil |

150.000 |

- |

100.000 |

- |

250.000 |

|

Car Lupo |

- |

- |

100.000 |

100.000 |

|

|

Car Berto |

- |

- |

250.000 |

- |

250.000 |

|

New Car Gabry |

- |

(200.000) |

- |

- |

(200.000) |

|

New Car Strega |

- |

- |

- |

(150.000) |

(150.000) |

|

Total for site |

450.000 |

400.000 |

350.000 |

450.000 |

1.650.000 |

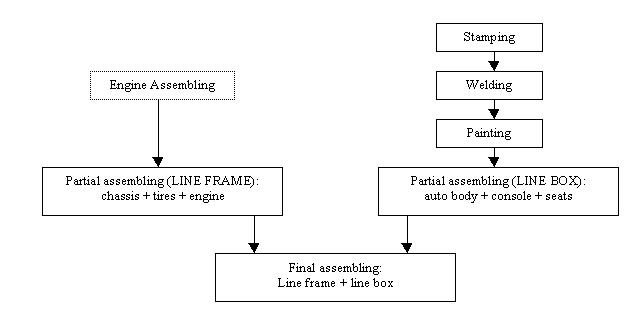

The cars are produced with the following flow chart:

On the line frame the chassis is assembled with tires and engine.

The engine assembling is done only in the site of Florissant. The other production sites buy directly the engine already assembled.

The auto body is produced through the phases of stamping, welding and painting.

On the line box the auto body is assembled with console and seats.

There is a final assembling line for to put together the parts which exit from the line frame and from line box.

For to become simpler the exercise, each car model is composed by only 6 components (chassis, tires, engine, auto body, console, seats).

Some components are bought at the external of the factory (chassis, tires, engine (excluded the Florissant site), console, seats); instead the auto body is produced at the internal of the factory.

The components bought at the external of the factory, are subdivide in 3 categories:

|

Car Model |

Chassis |

Tires |

Engine |

Console |

Seats |

|

Car Frenchie |

Chassis_B |

Tires_A |

Engine_A |

Console_A |

Seats_A |

|

Car Ago |

Chassis_B |

Tires_B |

Engine_B |

Console_C |

Seats_B |

|

Car Panettone |

Chassis_B |

Tires_B |

Console_B |

Seats_B |

|

|

Car Edsil |

Chassis_B |

Tires_B |

Engine_B |

Console_C |

Seats_B |

|

Car Lupo |

Chassis_B |

Tires_A |

Console_A |

Seats_A |

|

|

Car Berto |

Chassis_B |

Tires_B |

Engine_B |

Console_B |

Seats_B |

|

New Car Gabry |

Chassis_B |

Tires_A |

Engine_A |

Console_A |

Seats_B |

|

New Car Strega |

Chassis_B |

Tires_B |

Console_C |

Seats_A |

To produce the auto body, is necessary to buy steel which can be of:

The assembly of the engine is made only in the Florissant site, and all the pieces necessary are supplied directly by one factory.

|

Car Model |

Engine |

Auto body |

|

Car Frenchie |

Steel_A |

|

|

Car Ago |

Steel_B |

|

|

Car Panettone |

Mix_A |

Steel_A |

|

Car Edsil |

Steel_B |

|

|

Car Lupo |

Mix_A |

Steel_A |

|

Car Berto |

Steel_B |

|

|

New Car Gabry |

Steel_A |

|

|

New Car Strega |

Mix_A |

Steel_B |

Summarizing, in the system there are the following 13 components:

The are 15 suppliers (from SUP_1 through SUP_15) of components situated in:

Each supplier produces the components as follow:

|

Supplier |

Product |

Product |

Product |

|

SUP_1 |

Tires_A |

Tires_B |

|

|

SUP_2 |

Steel_B |

||

|

SUP_3 |

Console_A |

Console_B |

Console_C |

|

SUP_4 |

Seats_B |

||

|

SUP_5 |

Engine_A |

Mix_A |

|

|

SUP_6 |

Engine_A |

Engine_B |

|

|

SUP_7 |

Seats_A |

||

|

SUP_8 |

Tires_A |

Tires_B |

|

|

SUP_9 |

Engine_A |

||

|

SUP_10 |

Seats_A |

||

|

SUP_11 |

Steel_A |

Steel_B |

|

|

SUP_12 |

Console_C |

||

|

SUP_13 |

Mix_A |

||

|

SUP_14 |

Tires_B |

||

|

SUP_15 |

Engine_B |